As an Aussie 3D printing enthusiast, We've learned that the summer heat can be a formidable foe when it comes to maintaining the performance and reliability of my beloved machines. One of the most common issues we face during the hotter months is something known as "heat creep" – a pesky problem that can wreak havoc on our prints if not properly addressed.

TABLE OF CONTENTS

What is Heat Creep?

So, what exactly is heat creep, and how does it affect our 3D printing endeavors? In simple terms, heat creep is the phenomenon where the heat from the hot end of the printer gradually travels up the filament path, causing the filament to soften or even melt in the upper regions of the extruder. This can lead to a variety of issues, from extruder jams and clogs to inconsistent extrusion and even complete print failures.

The culprit behind heat creep is often the increased ambient temperature in our workshops or garages, which can raise the temperature within your hotend/extruder that meant to remain cold to ensure materials does not start to deform before reaching the hot side of the hotend. Enclosed printers, in particular, tend to be more susceptible to this problem, as the lack of airflow can trap the heat inside the build chamber an slowly increase chamber temperature, further exacerbating the issue.

To combat heat creep, there are a few strategies we can employ. For starters, if your printer has a door or top cover, it's often a good idea to remove them temporarily during the summer months. This allows for better airflow and helps dissipate the excess heat. If you have access to an air conditioning room, its may be good idea to move printer to those room but you need ensure airflow (from aircon) does not blow directly or near the printer as this cause change draft change causing print issues such as warping.

For those of us who work with materials that require a heated build chamber, such as ABS, the challenge becomes even more pronounced. In these cases, it might be necessary to lower the chamber temperature slightly to prevent the heat from building up too much, while still maintaining the elevated temperatures needed for proper layer adhesion for certain engineering materials such as ABS/ASA.

Of course, the specific solutions will vary depending on the design and features of your 3D printer, as well as the materials you're working with. It's always a good idea to consult the manufacturer's recommendations or seek advice from experienced members of the 3D printing community.

As we navigate the heat of the Aussie summer, it's important to remember that with a little bit of creativity and a willingness to experiment, we can overcome the challenges posed by heat creep and continue to produce amazing 3D printed creations. So, let's embrace the heat, stay cool, and keep those printers running smoothly!

Identifying and Addressing Heat Creep

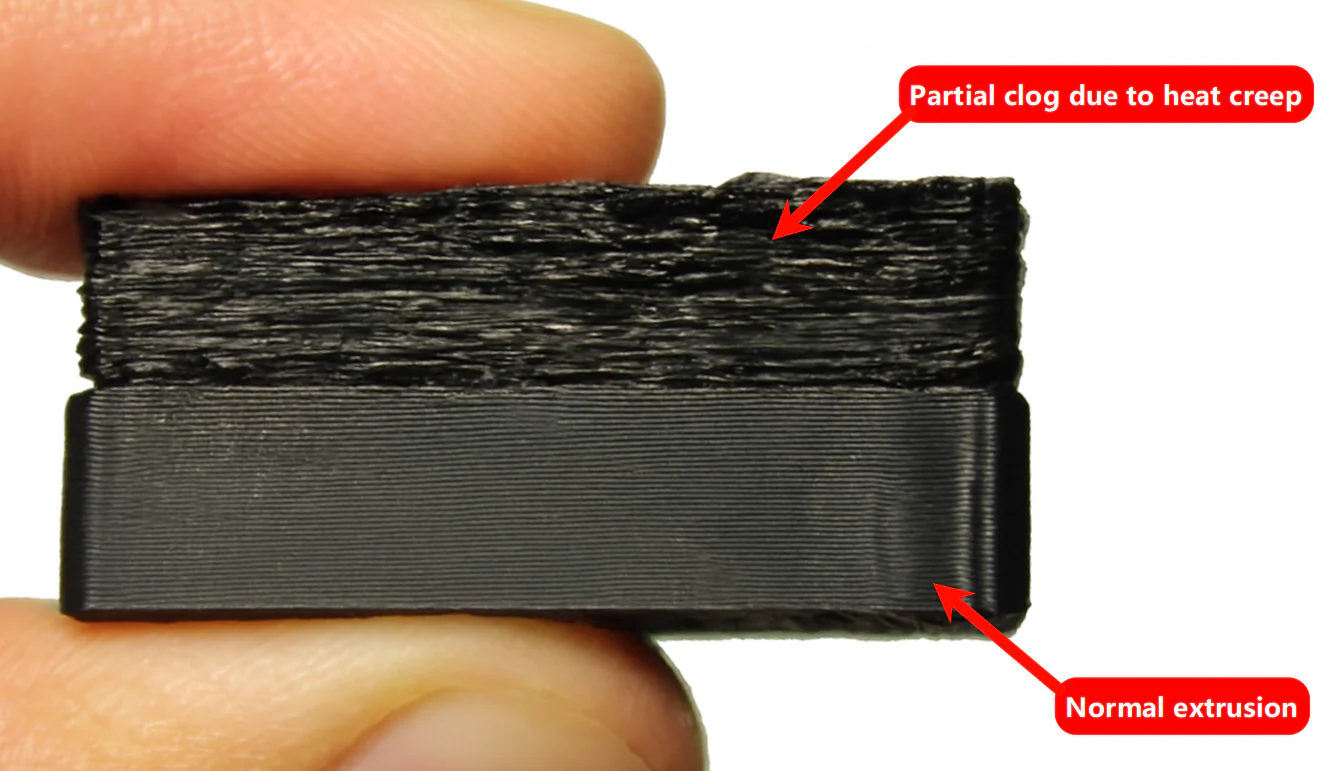

Heat creep can manifest in a few different ways, so it's important to be able to recognise the signs. Common symptoms include:

- Extruder jams or clogs

- Inconsistent extrusion or under-extrusion

- Filament softening or melting in the upper regions of the extruder

If you're experiencing any of these issues, it's a good indication that heat creep is at play. The next step is to identify the root cause and implement the appropriate solutions.

Image Source: https://wiki.bambulab.com/en/filament-acc/filament/heat-creep (Bambu Wiki)

Improving Airflow and Cooling

As mentioned earlier, enhancing airflow around your 3D printer can be a game-changer when it comes to combating heat creep. This can be achieved by removing any enclosures or covers, enable exhaust fans, or even considering the installation of additional cooling systems, such as active cooling for the hot end/extruder or the use of larger heat sinks but can sometimes not possible for most newer closed sourced machines (such as Bambu Labs) or limited space.

Adjusting Temperature Settings

Chamber

For materials that require a heated build chamber, it's important to find the right balance between maintaining the necessary temperatures and preventing excessive heat build-up. Experiment with lowering the chamber temperature slightly, while ensuring that your prints still adhere properly and maintain their structural integrity.

Bed Temperature

Another solution is lowering bed temperature, for example from 60c to 55c for PLA, as for most trident style 3d printer, where bed start at top of enclosure where higher bed temperature can increase bed temperature. A quick solution is using bed platform that can support bed printing temperature such as our DREMC Satin PEI , where you can print some materials around 10-20 or near room temperature which can significantly help reduce the heat build up within enclosed 3d printer.

Environment Temperature

You can consider removing top cover glass/top cover or remove the door, if you have fully enclosed printer which is design to trap heat usually for high temperature/engineering materials.

Preferable you want keep your chamber temperature well under materials softening temperature.

| Materials | Heatbed Temp | Upper Cover Plate Removed/Lifted? | Door Removed/Opened? |

|---|---|---|---|

| PLA/PLA-CF/PLA-GF | 45~60℃ | Yes | Yes |

| ABS | 90~110℃ | No | No |

| PETG/PETG-CF | 60~80℃ | No / Yes (If you experience heat creep) | No |

| PET-CF | 70~100℃ | No | No |

| TPU | 35~45℃ | Yes | Yes |

| ASA | 90~110℃ | No | No |

| PVA | 45~60℃ | Yes | Yes |

| PC/PC-CF | 90~120℃ | No | No |

| PA/PA-CF/PAHT-CF | 90~120℃ | No | No |

If you print between mixture of materials, you can consider printing a raiser unit where its allow you raise/remove your top cover easily.

Bambu 3D Printer Raisers Example: https://makerworld.com/en/models/1159424-top-lid-lifter-glass-riser-for-bambu-lab-p1-x1

K1 Max 3D Printer Raiser Example: https://www.printables.com/model/623798

Nozzle Temperature

If you're experiencing more heat creep within cold end of the hotend, you can checking cooling fan is functional and heat sink is clean of dust build up which can reduce the cooling efficiency.

You can reduce printing temperature, as some hotend temperature gradient between heat sink (cold end), heater block (hot end) may not be as efficient as other, sometimes reduce printing temperature can reduce the temperature of hotend cold side so its remains under softening temperature of the materials you're printing.

Choosing the Right Materials

Some filament materials are more susceptible to heat creep than others. If you're consistently struggling with this issue, it might be worth exploring alternative materials that are more heat-resistant or have a higher glass transition temperature. This can help mitigate the effects of the summer heat and keep your prints looking their best.

Remember, tackling heat creep is all about finding the right combination of strategies that work best for your specific 3D printing setup. With a little bit of trial and error, and a willingness to adapt to the changing conditions, you'll be well on your way to producing high-quality prints even in the midst of the Aussie summer heat.

Our team is always ready to help you and answer any questions you may have, you can reach out to DREMC Support.

Was this article helpful?

That’s Great!

Thank you for your feedback

Sorry! We couldn't be helpful

Thank you for your feedback

Feedback sent

We appreciate your effort and will try to fix the article